Research Results

Dec 15, 2020

- Press Release

- Joint Research Paper

A press release announcing the joint research findings of Assoc. Prof. Masazumi Tamura and Tohoku University has been issued to the media.

A New Method for Transforming Plastics into Valuable Chemicals

~A novel solid catalyst system has been developed for the efficient synthesis of valuable chemicals from polyolefin-based plastics at low temperatures~

This research presentation was introduced in the following media.

- January 14, 2021 The Chemical Daily

- February 8, 2021 The Chemical Daily

Key points of this study

- A novel solid catalyst has been developed that enables the efficient conversion of polyolefin-based plastics into valuable chemicals such as lubricants at low temperatures.

- Promising as a new solid catalyst technology for plastic conversion.

Summary

Associate Professor Masazumi Tamura (Research Center for Artificial Photosynthesis, Osaka City University), and Professor Keiichi Tomishige (Department of Applied Chemistry, Graduate School of Engineering, Tohoku University) have successfully developed a novel solid catalyst system that enables the efficient conversion of polyolefin-based plastics, which account for a large portion of plastic waste, into valuable chemicals such as lubricants and liquid chemicals at low temperatures.

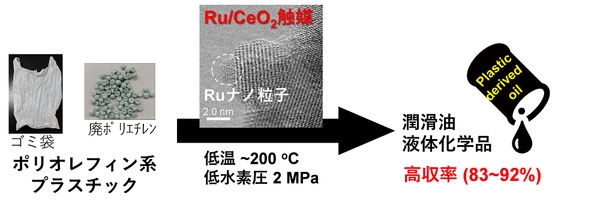

While oiling and gasification are known as chemical recycling technologies for polyolefin-based plastics, they have various issues. Therefore, there has been a strong demand for technologies that can convert plastics at low temperatures and for catalysts that enable direct and selective conversion into valuable chemical feedstocks. The developed ruthenium supported on ceria catalyst (Ru/CeO2) has achieved a significant reduction in reaction temperature by more than 100°C compared to conventional technologies. This catalyst can be applied to commercial garbage bags and other plastic waste, enabling the high-yield production of valuable chemicals. It is the world's first solid catalyst system capable of this.

The results of this research were published online in Applied Catalysis B: Environmental (IF = 16.68) on December 10, 2020.

Research Background

In recent years, plastic waste has become a global issue due to its impact on marine environments and ecosystems. Against this backdrop, there is a growing need to reduce the use of plastics and establish appropriate disposal methods. Additionally, from the perspective of resource circulation, technologies for recycling and reusing plastics have become increasingly important. Polyolefins account for a significant portion of plastic waste, making the development of recycling technologies for them a pressing issue. Among recycling technologies, chemical recycling is gaining attention as a process that can contribute to decarbonization, waste reduction, and the supply of feedstocks and chemicals. While oiling and gasification are known chemical recycling technologies for polyolefins, they typically require high temperatures exceeding 400°C and suffer from issues such as the production of low-value gases, significant amounts of byproducts, and catalyst deactivation. From the perspective of improving energy efficiency and reducing carbon dioxide emissions, there has been a strong demand for technologies that enable plastic conversion under low-temperature conditions and for catalysts that allow for the direct and selective conversion of plastics into high-value chemical feedstocks.

Outline of Research

Using polyethylene as a model substrate, we found that ruthenium supported on ceria (Ru/CeO2) exhibited higher catalytic activity compared to other metal-supported catalysts. This enabled the conversion of polyolefins under mild conditions, such as 200°C and 2 MPa hydrogen pressure, and resulted in high yields (over 90%) of valuable products like lubricants and liquid chemicals. Compared to previously reported solid catalysts, the developed catalyst enables the decomposition of polyolefin-based plastics at temperatures more than 100°C lower, demonstrating exceptionally high catalytic activity. Moreover, this solid catalyst system is applicable to commercial garbage bags and other plastic waste, achieving high yields of valuable chemicals.

Expected effect

This technology is expected to contribute to solving the plastic waste problem by enabling a circular economy for plastics. Additionally, by replacing the petrochemical processes used to synthesize chemicals, this technology is expected to reduce carbon dioxide emissions, energy consumption, and costs, thereby contributing to the construction of a low-carbon society.

Future Developments

For practical application, we will develop catalytic processes using actual waste plastics.

Financial Information

This research was conducted with the support of the Environmental Research and Technology Development Fund (JPMEERF20183R03) of the Environmental Restoration and Conservation Agency of Japan

Publication Information

| Publications: | Applied Catalysis B: Environmental (IF=16.68) |

|---|---|

| Title of Paper: | Low-Temperature Catalytic Upgrading of Waste Polyolefinic Plastics into Liquid Fuels and Waxes |

| Author: | Yosuke Nakaji, Masazumi Tamura*, Shuhei Miyaoka, Shogo Kumagai, Mifumi Tanji, Yoshinao Nakagawa, Toshiaki Yoshioka,Keiichi Tomishige* |

| URL: | https://www.sciencedirect.com/science/article/abs/pii/S0926337320312224 |